▪ About Us

▪ Product Center

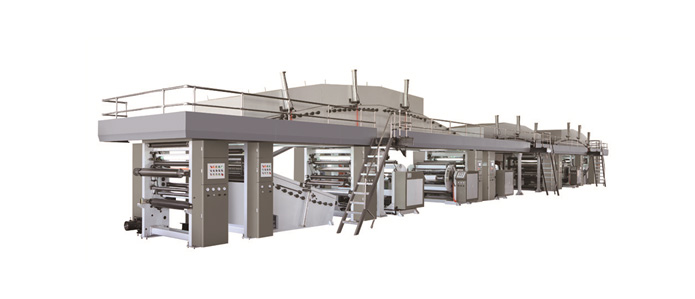

ZY-1300 PVDC Coating Machine

1.Features:

The whole machine is controlled by PLC system. It can set working parameters via touch screen of man-machine interface. Automatic receipt film without stop the machine with High speed, automatic closed loop tension control, ceramic anilox roll backing coating, inner oven and air supply system are structure of stainless steel, and it can be succession completed coating for four times one side.

2.Scope of application:

This machine is suitable for use in PVDC coating on BOPP、PET、PVC etc plastic film. As per different request on barrier property to milk, pharmaceutical,cigarette,and food package, we adopt multi coating.

3.Main Technical:

1 Max.Width of coating:1600mm

2 Max.Width of film guide roll:1600mm

3 Material for coating:PVC,BOPP,PET,PA

4 Thickness 0.02-0.40mm

5 Material of glue :PU primer,PVDC latex

6 Grammage : 40-60 g/ m2 ± 5%

7 The way of coating:once or twice coating succession completed,all adopt backing coating(PVDC Grammage 13-14g/m2).

8 Length of oven:whole length3×9m(surface coating)+1×3m(primer coating)

9 Heating method of oven:hot wind jet,efficient infrared ray preheat.

10 Temperature control of oven:normal temperature~130℃, automatic control,digit meter display.

11 EPC:EPC on exit of 3 sections surface coating oven

12 Diameter of roll:Unwind Max.Ø600mm,Rewind Max.Ф600mm,weight Max.1500kg.

13 Central shaft:Unwind,rewind adopt Ф3″or Ф6″ air shift,inner diameter of coil coatings tube Ф76mm or Ф152mm,active rewind permanent tension control,the reeling tension conical control,all drive vector inverter control by AC vector frequency motor.

14 Cooling :The exit of oven2×Ф295mm, covered the stainless steel to the surface of the cooling roll and the precision steel roll,mirror ultrafinish,match the rotary joint with water for cooling.

15 Machine speed:Max.180m/min。

16 Coating speed:150 m/min as per productive technology.

17 Control speed:Complete machine adopt introduced vector frequency control of motor speed.

18 Control system:Complete machine adopt PLC in control system, man-machine touch screem.

19 Drive:Full AC vector frequency motor synchronized drive(with rotary encoder).

20 Oven:haveing two layers,pneumatic top open for the upper layer cylinder(with security protection poles)

21 Power supply:380V 50HZ

22 Total power:about 320kw

23 Overall dimension:37M×3.4M×5.4M (L×W×H)

24 Total weight:About 30T